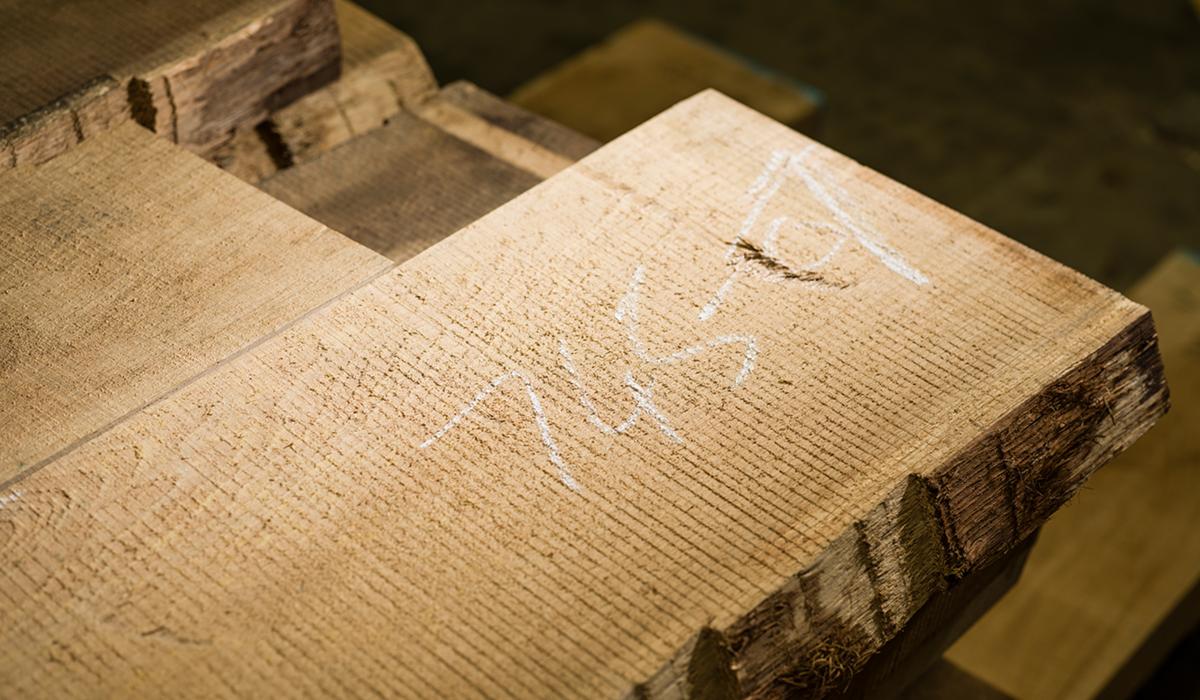

Since 1973, Oyster craftsmanship has drawn on the long tradition of boat building in Norfolk and Southampton, by working with local experts Landamores and Windboats in Norfolk, both founded over 100 years ago, and in Southampton, with SYS, a prestige shipyard, building up to 25m superyachts. Together, they created the foundation for Oyster’s dedication to design, craftsmanship and attention to detail that continues today.